Taking it to the Next Level

By: Chris Mc Loone

packagePRINTING // January 1, 2009

Flexographic printing quality has been approaching that of gravure for some time now. Although it has been attractive to printers due to its lower price point than gravure printing, one of flexo’s shortfalls has always been that its quality is not at the same level as gravure. Trisoft Graphics, Inc. (www.trisoftco.com)—a digital prepress and graphic design company serving the packaging industry since 1993—recently installed a new flexographic platemaking system it expects to use to produce flexographic printing plates that, when employed, will rival gravure’s quality.

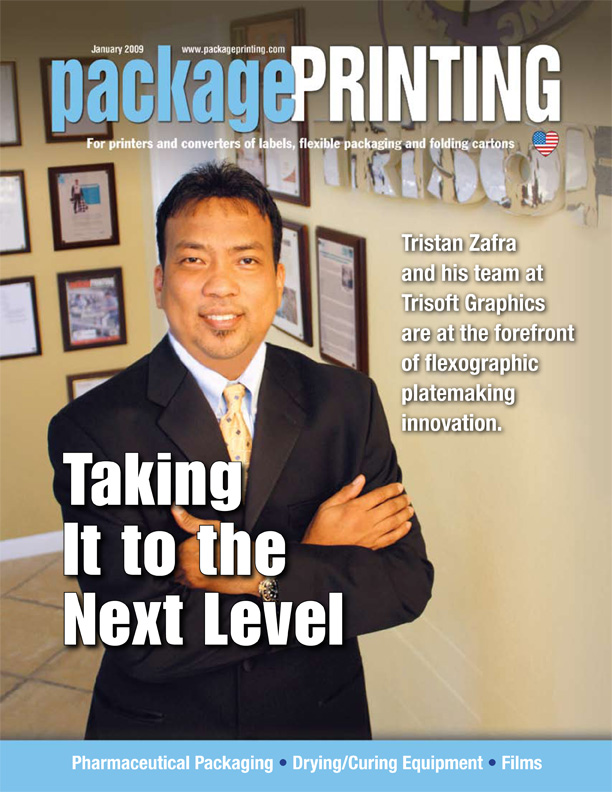

Trisoft has more than 15 years experience specializing in flexography, prepress, and platemaking. According to Tristan Zafra, owner, the company designs for labels, folding cartons and flexible packaging industries for materials that include polypropylene, craft stock, and vinyl. The company is very hands-on in its approach to its customers, says Zafra. “We pride ourselves on innovation and always look at new -technologies,” he says. “We have a team of very experienced and knowledgeable people. We take a very hands-on approach to all of our customer needs.” For instance, to avoid communication mixups that might -hinder a customer’s project progress, the company connects customers directly to a graphic artist. The company’s staff works directly and closely with the customer during the entire project, every step of the way. Doing so helps the company remain true to its core operating philosophy,which, according to Zafra, is “to produce the best quality flexo plates and to offer the absolute best in customer service satisfaction.”